What is a Strapping System and How Does it Work?

What Is A Strapping System?

A strapping machine is a mechanical device known to speed up the process of wrapping pallets or products in various materials to prevent the product from separating in transit.

The strapping band is available in various sizes and strengths to allow your products to stay tightly packed and to ensure they are held together during transportation or handling. There are a variety of strapping machines available, like semi-automatic strapping machines, automatic strapping machines, and handheld strapping machines.

How Do The Different Types Of Systems Work?

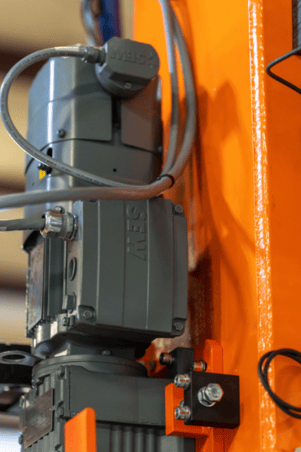

Automatic Strapping System - a high-performance method of packaging goods. The strapping system feeds bundles into the arch via a conveyor belt. Each machine is completely automated with sensors that activate each package's strapping and sealing process.

These systems can dispense up to 65 straps per minute in one smooth motion, sealing and cutting the strap to each size needed. Since these systems are fully automatic, they do not require a manual operator. These machines are suitable for high-volume lines.

Semi-Automatic Strapping System - a machine that requires someone to operate it. An employee must manually place the product that needs strapping on the machine table. After placement, the employee puts a band around the product and manually places it into the slot to begin the strapping cycle. The machine will pull the strapping band tightly around the product to seal the ends of the strap.

The machine will automatically cut the strap to complete the process, and the product is ready to be transported. These machines are suitable for lower-volume businesses because they are practical and economical.

Handheld Strapping System - a small, portable strapping device with different components compared to the larger machines. The small handheld systems are simple to operate, lightweight and easily portable. To operate, manually loop the strapping around the pallet, product or parcel. Once fully looped, the operator must feed both ends into the handheld machine.

Carefully, the operator must pull the lever on the machine to tighten and tension the strap. Because the machine is handheld, it can be used vertically or horizontally, with the ability to set the desired tension strength on the device.

How Can A Strapping System Help Your Business?

There are numerous ways that a strapping system can help your business, automated or not. For starters, a strapping machine lowers the number of employees you need to strap the products manually. With a strapping system, you may only need one employee to keep an eye on the machine. This allows your workers to focus their time and energy on other business needs to produce revenue.

1. Greater Efficiency - a reliable strapping system for your business can resolve inefficiency whilst boosting performance in crucial areas. Using an automated strapping system, your business will use less material as the straps are measured precisely for each package.

Employers tend to overestimate the length and will eventually use more material over a long period of time. On top of precision, the strapping systems are much faster than manual strapping, resulting in less material waste and a much quicker strapping process.

2. Cut Costs - strapping systems are reliable, and if maintenance is ongoing, you can stretch the lifespan of individual parts, ultimately lowering their lifetime cost. A strapping machine can double your output in production, decreasing the amount of human labour used in other business sectors.

3. Fewer Errors - manual strapping techniques may present many concerns when packaging products. They tend to slip off of the product and can tend to allow for more shifting during the shipping and handling process. If the strap becomes loose, the products become vulnerable and may even damage.

Because automated strapping machines are consistent with wrapping products with precise tension, this reduces material waste by only cutting the amount needed to wrap the product with the exact amount of tension.

4. Increased Safety - automated strapping systems keep workers from dangerous packaging processes. Because the systems use sensors and automated technology, this removes the manual, repetitive motions, which increases fatigue, and inevitably increases the likelihood of accidents occurring.

5. Increased Customer Satisfaction - by incorporating an automated strapping system, you decrease the time it takes to deliver products to their destination, ultimately increasing customer satisfaction. With improper strapping methods, your products could shift in delivery and possibly lead to tamped or damaged goods. Using automated strapping systems creates a distinctive imprint in your products, making them hard to remove or tamper with while en route.

Automated strapping systems create a safer, more efficient work environment that cuts costs and improves efficiency. There are many factors to consider when choosing your strapping system, and finding the most reliable machines is crucial for your business.

The experts at Itipack are trained and qualified to help you assess your needs and make the most suitable decision for your business. Schedule a meeting with one of our experts to get a quote for a customized strapping solution!