The Top Strapping Machine Trends of 2023

The strapping machine industry is set for remarkable growth, with projections indicating that the global market will reach an impressive $7 billion by 2030, up from $4 billion in 2022. This rapid growth results from technological advancements, the drive for increased efficiency, and the changing needs of various industries. To succeed in this evolving landscape, businesses must stay updated on the latest developments in the strapping systems sector. So let’s explore the top strapping machine trends of 2023, which have reshaped the industry and beyond, leading to safer and more dependable transportation of goods.

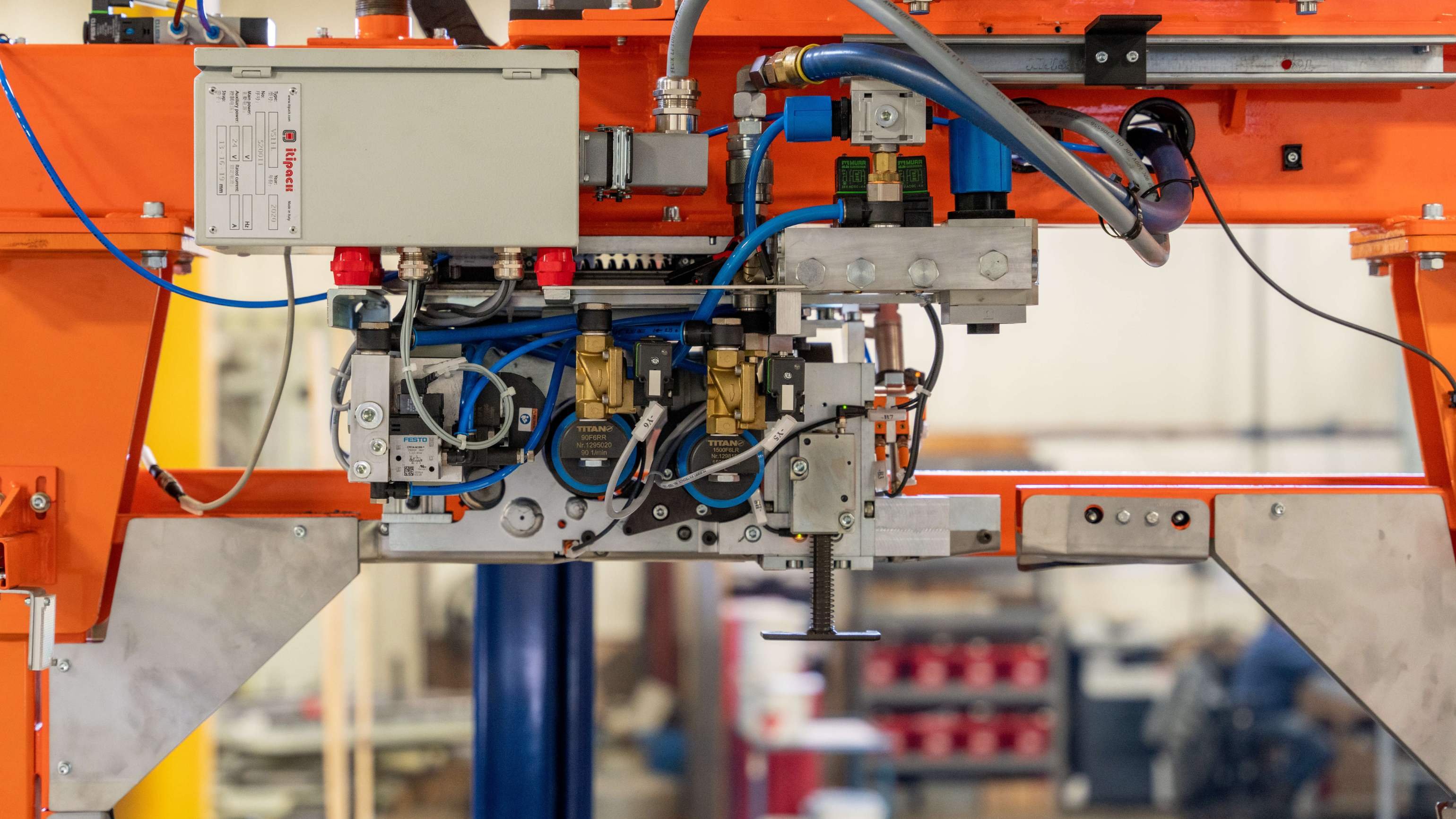

Trapping companies have adapted to the changing landscape in sync with the global economy. As we move into 2023, the market is driven by sustainability and automation trends, and Itipack Systems remains at the forefront by continuously innovating its products and tailored solutions. These advancements empower customers to boost productivity, reduce maintenance expenses, prioritize sustainability, and minimize their environmental impact by reducing carbon footprints.

The Evolution of Strapping Machines

Examining the historical backdrop of strapping machines provides valuable insights into the formulation of current strapping system trends in the industry. The origins of strapping systems can be traced back to the early 20th century, marking the initial steps toward the development of modern strapping technology. It is deeply intertwined with the transformation of industries and the need for secure goods transportation. From humble beginnings to the present day, these systems have played a crucial role in ensuring the safe delivery of products across various sectors.

The introduction of steel strapping in the early 1900s revolutionized packaging and shipping practices. Steel bands were used to secure heavy loads and provide greater stability during transportation. Later in the mid-20th century, automatic strapping machines replaced manual methods, increasing speed and efficiency through motorized systems. Automated strapping machinery streamlined operations, improving packaging integrity and reducing transit damage. Materials expanded beyond steel to include polyester and polypropylene, offering flexibility, weather resistance, and corrosion resistance.

Today's strapping systems are highly efficient, with cutting-edge materials and designs which cater to different industries. They offer enhanced strength, flexibility, and adaptability, aided by smart technologies like IoT sensors and automated control systems for precise monitoring.

With technological advancements, the strapping machinery industry embraced automation and computerization. Modern strapping machines are equipped with advanced controls, sensors, and programmable settings, allowing for precise and customizable strapping operations.

The future of strapping systems holds promise as advancements in materials science and engineering are expected to yield stronger, lighter, and more eco-friendly options. The integration of robotics and artificial intelligence can further automate processes, ensuring faster and more accurate operations. Additionally, data analytics and predictive maintenance techniques could optimize performance and minimize downtime by proactively identifying maintenance needs. These developments collectively enhance the efficiency, reliability, and sustainability of strapping systems, benefiting industries reliant on effective strapping solutions.

Strapping Machines Trends Forecast

As the demand for strapping solutions continues to grow across various industries, the strapping industry itself is expanding rapidly. This presents an exciting opportunity for Itipack to provide businesses with cutting-edge strapping solutions that align with the two major strapping machine trends of 2023: sustainability and automation. By offering innovative and customized strapping solutions, Itipack aims to meet the evolving needs of businesses while staying ahead of the curve in the industry. With a focus on sustainability and the integration of automation, Itipack is dedicated to delivering high-quality and forward-thinking strapping solutions to its customers.

Sustainability Trends in Strapping Systems

Strapping machines play a crucial role in various industries, and their integration with sustainability practices is becoming increasingly important. This is especially true due to the rising demand for sustainable packaging solutions, driven by bans on single-use packaging in various regions around the world. Consequently, the strapping supplies market is witnessing a shift towards greater sustainability to meet these changing industry requirements.

Sustainable strapping systems aim to minimize environmental impact throughout their lifecycle. One key aspect is the development of eco-friendly strapping materials, such as biodegradable or recyclable options, reducing waste and promoting circularity. Let’s look at some examples of eco-friendly strapping materials being explored and utilized in various industries.

Biodegradable Polyesters

Biodegradable polyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are derived from renewable resources like corn starch or sugarcane. These materials have the advantage of being compostable, breaking down naturally over time, and reducing environmental impact.

Recycled Plastic Straps

Utilizing recycled plastics, such as polyethylene terephthalate (PET), to create strapping materials helps divert waste from landfills and reduces the need for virgin plastics. Recycled plastic straps can exhibit similar strength and durability to traditional straps while significantly reducing their carbon footprint.

Paper Straps

Paper straps, often made from recycled or sustainably sourced paper, are an eco-friendly alternative to plastic straps. They are recyclable, biodegradable, and suitable for lightweight packaging applications. Paper straps are commonly used in industries where minimal strap strength is required.

Bio-Based Polymer Straps

Bio-based polymer straps are made from renewable resources, such as plant-based feedstocks. These straps offer reduced carbon emissions compared to conventional plastics. They can be designed to have similar properties to traditional strapping materials, making them suitable for a wide range of applications.

Natural Fiber Straps

Straps made from natural fibres, such as cotton, jute or hemp, are renewable, biodegradable, and have a lower environmental impact compared to synthetic alternatives. These materials are suitable for certain light to medium-duty applications and offer a sustainable alternative for specific industries.

It is worth noting that the suitability of these eco-friendly strapping materials may vary depending on specific requirements, load capacities, and environmental conditions. Industries and businesses should consider their unique needs when selecting the most appropriate eco-friendly strapping material for their applications.

Advanced Automation Trends in Strapping Systems

The increasing demand for cost-effective and time-efficient strapping solutions and the goal of minimizing wastage is driving the need for advanced automated strapping systems.

Automated strapping systems, equipped with advanced technologies such as robotics, artificial intelligence, and advanced sensors, are revolutionizing the strapping process. These automated systems have the capability to intelligently analyze package characteristics, such as size, weight, and shape, and select the optimal strapping method accordingly.

Automation does not aim to replace people but rather to liberate them from mundane and repetitive tasks. Fred Townes, the chief product officer at READY Education, says, “For small businesses, the most important thing is [repetition]. When you find something you do more than once that adds value … you want to look into automation.”

Advanced automation enhances operational safety and reliability by eliminating the need for manual labour and reducing human error. Furthermore, automated strapping systems can operate at high speeds, resulting in faster throughput and increased productivity. As businesses strive to achieve greater efficiency, the adoption of advanced automation in strapping machines becomes a significant driver of progress and competitiveness in the industry.

Asset Tracking and Management Technology

![]()

RFID ( Radio Frequency Identification)

RFID asset tracking systems will play a vital role in enhancing automation for strapping machines. By utilizing RFID technology, these systems enable seamless identification and tracking of assets throughout the strapping process. RFID technology provides several benefits for the strapping process, including:

- RFID tags with unique identifiers are affixed to assets or packages.

- RFID readers capture tag information, enabling real-time tracking and monitoring.

- Manual scanning and data entry is eliminated, saving time and reducing errors.

- RFID systems integrate with strapping machines to trigger appropriate parameters based on tag information.

- Automatic routing and sorting of assets optimize workflow and minimize bottlenecks.

- RFID data can be analyzed for insights, improving resource allocation and identifying areas for further automation and process improvement.

IoT (Internet of Things)

The Internet of Things (IoT) can contribute to the automation process of strapping systems by providing real-time monitoring, condition monitoring, process optimization, error detection, and integration capabilities. Their implementation improves accuracy, reliability, and overall performance, resulting in enhanced productivity and operational efficiency. Furthermore, the use of IoT in strapping machines can help:

- Enable connectivity and data exchange for seamless communication.

- Allow remote monitoring and control for efficient management.

- Support predictive maintenance to reduce downtime and optimize performance.

- Provide data analytics for process optimization and productivity improvement.

- Monitor the condition of strapping components, facilitating proactive maintenance and reducing downtime.

- Detects anomalies during strapping, triggering alerts or automatic adjustments to ensure consistent quality.

- Seamlessly integrate with automated strapping systems for real-time communication and synchronized adjustments.

Itipack’s Commitment

At Itipack Systems, our dedication lies in delivering our customers the best strapping machine solutions and products. We ensure that our offerings incorporate the latest technology and adhere to sustainability standards. No matter what industry you belong to, our team of experts will work diligently to identify a solution that precisely meets the unique requirements of your business.

Contact us today to learn more about our services.